Q: How long does it typically take to establish operations in Mexico?

A: Timeframes vary based on project complexity, but most manufacturing operations can be operational within 9-12 months from initial planning. Distribution operations often move faster, with 4-6 month implementations possible for straightforward projects.

Q: What regions of Mexico are best for my industry?

A: The optimal location depends on your specific requirements. Manufacturing operations often benefit from central Mexico's industrial clusters, technology functions excel in Guadalajara and Mexico City, while logistics operations may prioritize border proximity. Our location analysis process identifies the best match for your unique needs.

Q: How do we manage quality control in a nearshored operation?

A: Mexico's proximity enables much more frequent in-person oversight than offshore locations. Additionally, many companies implement digital quality management systems, regular audits, and training programs to ensure consistent standards. The shared time zones facilitate real-time communication about quality matters.

Q: What are the tax implications of establishing operations in Mexico?

A: Mexico offers various structures for foreign operations with different tax implications. Most manufacturing operations utilize the IMMEX program, which provides import duty exemptions for materials that will be processed and exported. Our tax specialists can outline the options most advantageous for your specific situation.

Q: How do we ensure protection of our intellectual property?

A: Mexico provides strong IP protections under the USMCA, including patent enforcement, trademark registration, and trade secret provisions. Discovery CRE helps clients implement appropriate security measures and legal frameworks to safeguard proprietary technologies and processes.

Q: What support is available for employee training and development?

A: Mexico offers various programs supporting workforce development, including federal and state training incentives. Many locations have technical education institutions that can develop customized programs for specific industry needs. Discovery CRE connects clients with these resources to build skilled teams.

Q: How do we handle currency risk in our Mexico operations?

A: Companies typically employ a combination of natural hedging (balancing peso expenses with peso revenue where possible), financial instruments, and procurement strategies to manage currency exposure. Our financial partners can help develop appropriate strategies for your specific situation.

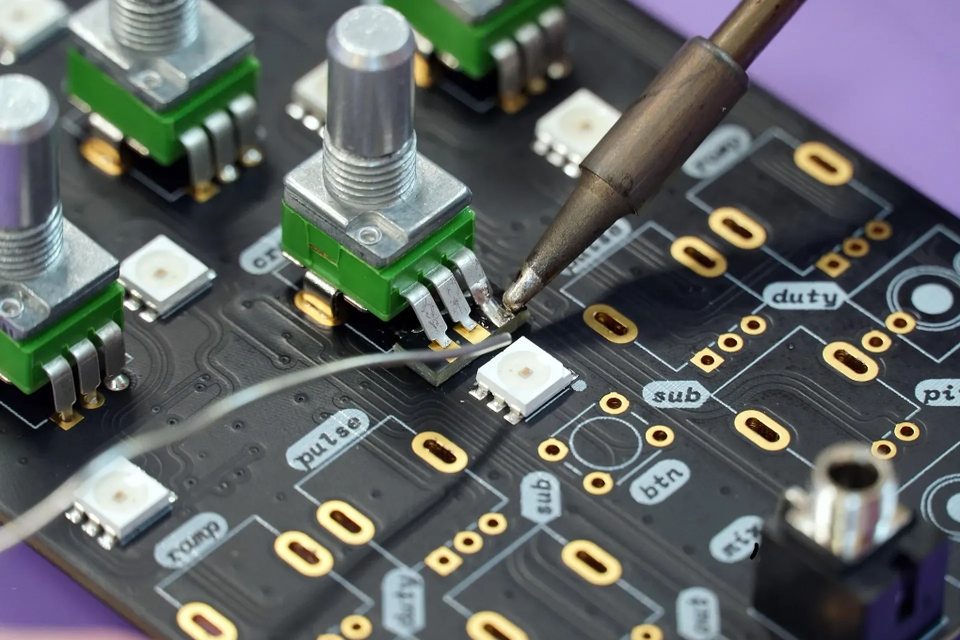

Q: What industries are seeing the most success with nearshoring to Mexico?

A: While Mexico supports diverse sectors, particular success has been seen in automotive (including EV production), aerospace, electronics, medical devices, furniture manufacturing, and textile production. The technology sector is also growing rapidly, especially in software development, IT services, and electronics R&D.

Q: How do rising global energy costs impact the nearshoring equation?

A: Increasing energy costs have strengthened Mexico's nearshoring advantage by dramatically raising the expense of long-distance shipping from Asia to North America. Additionally, Mexico offers competitive energy rates in many regions and significant opportunities for renewable energy implementation, particularly solar in northern states.

Q: What technological infrastructure is available to support digital operations in Mexico?

A: Mexico has invested heavily in telecommunications infrastructure, with high-speed fiber connectivity available in all major business centers. Cloud service providers maintain data centers within Mexico, major technology providers offer local support, and the country produces over 130,000 IT graduates annually.

Q: How do Mexican workers compare in terms of productivity and skills development?

A: Mexican manufacturing productivity rivals global standards, with automotive plants achieving efficiency metrics comparable to their U.S. counterparts. The workforce demonstrates strong technical aptitude, with workers typically mastering complex processes more rapidly than in many alternative locations.

Q: What supplier ecosystems exist within Mexico to support nearshored operations?

A: Mexico has developed sophisticated supplier networks in several sectors, notably automotive (with over 600 Tier 1 suppliers), aerospace (with comprehensive certification programs), electronics, and increasingly, medical devices. These ecosystems enable local sourcing that further reduces costs and improves supply chain resilience.

Q: How are companies handling the transition period when establishing Mexico operations?

A: Successful transitions typically involve phased approaches rather than abrupt shifts. Common strategies include establishing pilot operations while maintaining existing production, gradually transferring product lines, implementing robust knowledge transfer protocols, and developing binational management teams.

Q: What financing options are available for establishing Mexico operations?

A: Companies can access diverse funding mechanisms including specialized real estate investment vehicles for industrial properties, Mexican development bank programs supporting foreign investment, equipment leasing structures, incentive packages from state governments, and private equity partners focused on Mexico's industrial growth.

Q: How does Mexico's higher education system support nearshoring operations?

A: Mexico graduates over 120,000 engineers annually, with increasing specialization in fields aligned with advanced manufacturing and technology operations. Leading universities have established industry partnerships that influence curriculum development, provide internship pipelines, and support applied research initiatives.